Textile finishing changes raw fabrics into ready-to-wear materials meeting everyday use and market demands. In this informative guide, we will take a look at popular textile finishing solutions for cotton, polyester and their blends.

Get to know what is finishing in textile what finishes are classified in textiles and types of finishing in textiles like chemical and mechanical methods.

You’ll find practical details on the textile finishing process of each fabric type based on industry practice to enable manufacturers to achieve durability, comfort and performance.

Discover how Colourinn supports these processes with reliable auxiliaries.

Overview: Textile Finishing

- Core Purpose: Textile finishing improves fabric characteristics such as softness, wrinkle resistance, and color fastness; materials are used for apparel and home goods.

- Process Integration: It comes after weaving/knitting and includes scouring, dyeing and final treatments to make fabrics ready for end-use.

- Material Focus: Solutions depend on fibre type. Cotton has moisture management, polyester has heat stability and blends have balanced multifunctional effects.

- Industry Standards: Follows guidelines from bodies such as the International Textile Manufacturers Federation (ITMF) for sustainability & performance testing.

- Key Challenges: Balancing cost, environmental impact and durability for export-grade products in particular.

What is Finishing in Textile?

Finishing is the last operation in textile production; here, treatments are applied to upgrade the fabric properties and performance. This step corrects problems from earlier processes such as uneven dyeing and stiffness, and adds value through feel, performance improvements.

Industry experts define finishing in textiles as a combination of preparatory, dyeing and post-treatments according to end-product requirements. Cotton yarns for example absorb moisture whereas polyester threads resist static buildup.

- Preparatory Role: Removing impurities and preparing surfaces for chemical uptake – important for blends to avoid weak spots.

- Functional Enhancements: Adds water repellency/flame resistance properties tested by standards like ASTM.

- Economic Impact: Hand feel reduces returns by 20-30% and boosts fabric value, Textile World reports.

- Sustainability Angle: Modern approaches have low-water methods and follow global regulations to cut the environmental footprint.

- Quality Checks: Metrics include color transfer by crocking and wear resistance by tensile strength.

Classification of Finishes in Textiles

The finishing classification of textiles groups treatments by durability, application method or purpose to enable producers to select options for specific fabrics. It dictates whether a finish will wash out or survive repeated laundries. Cotton needs to be semi-durable for everyday wear, polyester permanent for stability, and a mix if you want compatibility.

- Temporary Finishes: Wash away after 1 or 2 cycles; ideal for cotton trial runs to see how aesthetics hold up without committing.

- Semi-Durable Finishes: Withstand 10-20 washes; keeping shape is common in polyester blends used for workwear.

- Permanent Finishes: Endure 50+ washes; applied via resins to cotton for wrinkle-free shirts.

- Functional Finishes: In blends, target antimicrobial performance. chitosan treatments last for up to 30 washes.

- Aesthetic Finishes: Focus on look & feel; mechanical options for polyester sheen without chemicals.

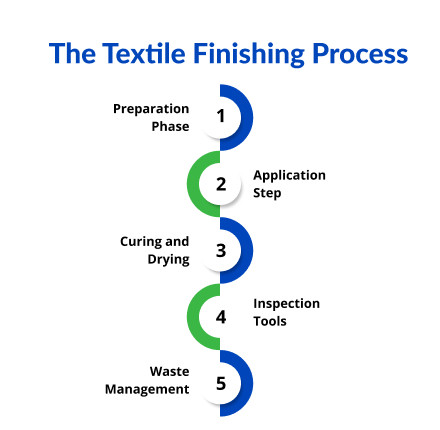

The Textile Finishing Process

The textile finishing process has a specific sequence i.e preparation, application, curing and inspection. Mills begin by scouring clean fibers and finish with baths or machines. For blends this guarantees polyester’s slickness against cotton’s breathability, without separation risks.

The process also adapts to fiber blends where cotton impurities are broken down first by polyester-compatible resins. Timing matters; Polyester melts when it gets too hot.

- Preparation Phase: Scour and bleach to remove oils; important if cotton is to take dyes evenly.

- Application Step: Finishes with dip or spray finishes; For polyester efficiency, 1-5% chemical load on fabric weight is acceptable.

- Curing and Drying: For resins, heat at 120-150°C; Shrinkage of cotton-poly blends is kept below 3%.

- Inspection Tools: Use pH meters & tensile tester; Ensures wash durability in accordance with ISO 6330.

- Waste Management: Recycle bath water; Modern setups reduce environmental load by 40%.

Chemical Finishing of Textiles

Compounds used for chemical finishing of textiles change fibre properties such as resilience or repellency. This works well with cotton for mercerization, which swells fibres for lustre, and polyester for silicone treatments in textile that ease sewing. Blends need balanced formulas so polyester does not dominate the feel.

- Softening Agents: Cotton plushness quaternary compounds; lab tests reduce friction by 25%.

- Resin Treatments: Cross-link fibers in polyester for shape retention; For blends, applied at pH 5-6.

- Water-Repellent Finishes: For outdoor gear: fluorocarbons on cotton-poly; withstand 20 launderings.

- Flame-Retardant Options: For workwear blends: phosphorus compounds; Meet NFPA 701 standards.

- Eco-Friendly Variants: A enzyme based method for cotton desizing. Reduce energy use by 30% compared to traditional acids.

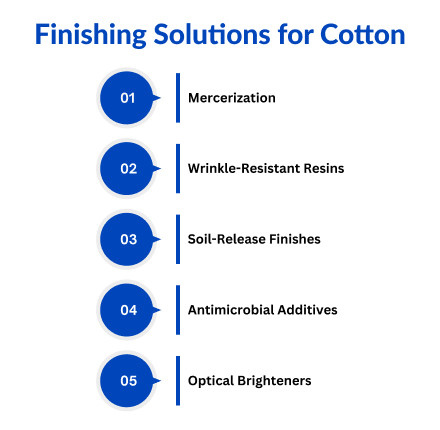

Finishing Solutions for Cotton

Cotton prized for breathability requires textile finishing that preserves its natural characteristics while being tough. Caustic soda mercerization increases yarn uptake and strength up to 20% tensile gain.

The stiffness from weaving is tempered by softening. Mills apply these in batch systems focusing on absorbency for towels or shirting.

- Mercerization: For luster: alkaline treatment; improves cotton elongation by 12%.

- Wrinkle-Resistant Resins: DMDHEU for shirts; Maintains flat press after 40 washes.

- Soil-Release Finishes: Polymers for easier cleaning; reduce stain retention by 50%.

- Antimicrobial Additives: For sportswear: silver ions inhibit bacteria growth per AATCC 100.

- Optical Brighteners: For whiter cottons; boost reflectance without yellowing.

Finishing Solutions for Polyester

Polyester is synthetic so textile finishing should stabilize heat-sensitive fibers and prevent static. Heat settings at 190-220°C fixes dimensions, so knits do not shrink. Anti-static sprays are used for comfort in activewear. ITMF industry reports recommend low chemical loads to avoid buildup on smooth surfaces.

- Heat-Setting: Locks molecular structure; controls distortion to less than 2%.

- Anti-Static Treatments: Quaternary amines; reducing surface resistivity by 70%.

- Dye Fixation: Carriers for even colour; vital post-extrusion.

- UV Protection: Additives for outdoor fabrics; Colour life extends by 50%.

- Silicone Emulsions: For slipperiness; ease of garment assembly.

Finishing Solutions for Blends

Blends such as cotton-polyester (65/35) require textile finishing that matches fibers for example resins for cotton wrinkle control and silicones for polyester. Multifunctional chitosan finishes add antimicrobial properties and last 20-30 washes per PMC studies.

Processes such as pad-dry-cure guarantee an even penetration. PH 4-6 & concentrations (2-5%) are optimized for easy-care effect without stiffness.

- Easy-Care Resins: Cross-link both fibers; ensure 90° crease recovery.

- Multifunctional Coatings: Cocktails of enzymes for separation resistance.

- Softener Blends: Cationic for cotton, non-ionic for poly; balance hand feel.

- Shrinkage Control: Sanforizing plus resins; in blends, limit to 1.5%.

- Performance Testing: Launder ISO 6330; verify no delamination.

Colourinn’s Role in Textile Finishing

We have explored how textile finishing changes cotton, polyester and blends through specific processes and finishes. These solutions provide the softness, strength and sustainability that global markets demand from understanding what finishing in textile to chemical finishing of textiles & mechanical finishes in textiles.

Need help refining your fabrics?

Our textile dyeing auxiliaries and reactive dyes are available for all steps of the textile finishing process. For custom formulations or samples: contact our experts in bringing your blends alive!